Purpose-Built Facilities Engineered for Scale

Veira operates a formidable network of modern manufacturing facilities, boasting nearly one million sq. ft. of production space. Our infrastructure is meticulously designed to support high-volume, high-quality production across a diverse portfolio.

0

Factories

0+

Employees

0

Subsidiary Offices

0

Service Partners

LED TV Setup, Infrastructure & Capacity

Our primary plant at A3A Sector 81, Noida, spans approximately 500,000 sq. ft. and is equipped with 2 SMT Lines, 3 MI Lines, 6 FA Lines, and 2 LCM Lines, boasting an annual capacity of 3 Million units. It is powered by a team of over 1000 professionals, including dedicated teams for quality, R&D, and NPI.

In-House Capabilities & Systems

We maintain full control over our production quality with robust in-house capabilities. Our operations are powered by MES and SAP-enabled ERP systems, ensuring real-time monitoring and efficiency. We are an ISO 9001, 14001, & 45001 accredited organization, also holding ESD 20:20, Ecovadis, and Sedex certifications.

Modern Office & Workspace Design

Our manufacturing excellence is complemented by modern workspaces designed to elevate quality, foster collaboration, and drive productivity. Our facilities include state-of-the-art office setups, conference rooms, and product showrooms that reflect our commitment to a world-class operational environment.

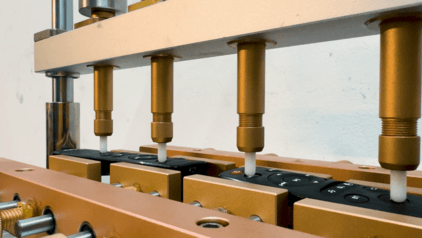

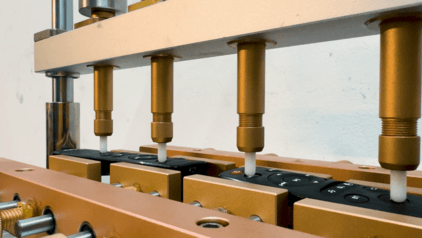

Automation that combines Speed with Unrivalled Precision

At Veira, our manufacturing prowess stems from a synergistic blend of cutting-edge automated systems and the expertise of highly skilled operators. This fusion enables us to deliver not just consistent throughput, but also impeccable quality with complete traceability across every single unit.

- High-speed SMT & Manual Insertion for robust main-board assembly

- Multiple advanced LCM (Liquid Crystal Module) lines within dual 10K clean rooms, critical for pristine display production

- Over 6 fully automatic FA (Final Assembly) lines, ensuring precision for displays and consumer electronics products

- Sophisticated robotic pick-and-place systems and zero-handling automated packaging, minimizing human error and maximizing efficiency

- 10 in-house plastic moulding presses with capacities up to 2,200T, enabling large-scale production of complex housings and components

- Integrated MES (Manufacturing Execution System) for real-time process control, traceability, and optimization across all lines

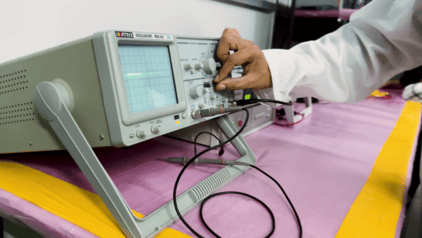

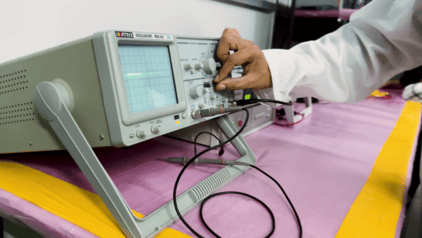

Quality Engineered Into Every Step

Quality at Veira is not just a final inspection; it's a foundational principle engineered into our manufacturing DNA. We employ a multi-layered approach to quality assurance, ensuring every product that leaves our facility not only meets but exceeds international standards of excellence, reliability, and safety.

- Comprehensive environmental testing in humidity, dust, temperature, vibration, and aging chambers to simulate real-world conditions.

- 100% barcode tracking integrated with a Manufacturing Execution System (MES) for granular, real-time process control and complete product traceability.

- Strict adherence to zero-dust production protocols, verified by 3rd-party audits and maintained through advanced 10K clean-room environments.

- A dedicated, in-house R&D and Quality Assurance team driving a culture of continuous improvement through rigorous analysis and feedback loops.

- ISO 9001, 14001, & 45001 accreditations, alongside certifications like ESD 20:20, Ecovadis, and Sedex, underscoring our commitment to global standards.